In the world of machinery and automotive industries, selecting the right Spare Parts Filter is crucial. Reports indicate that up to 30% of equipment failures stem from poor parts selection. A faulty filter can lead to inefficient performance, increasing operational costs. The right Spare Parts Filter ensures longevity and reliability.

Choosing the correct filter involves understanding specific needs. Each machine has unique parameters. It's important to consider compatibility, quality standards, and manufacturer recommendations. According to a recent survey, 45% of maintenance professionals reported issues due to mismatched filters. This highlights a common oversight that can be easily avoided.

When sourcing Spare Parts Filters, one should account for various factors like price versus performance. Opting for low-cost filters could result in higher expenses down the line. Also, suppliers with a strong reputation often offer better customer support. It’s essential to revisit choices regularly to ensure optimal functionality and avoid unexpected repairs.

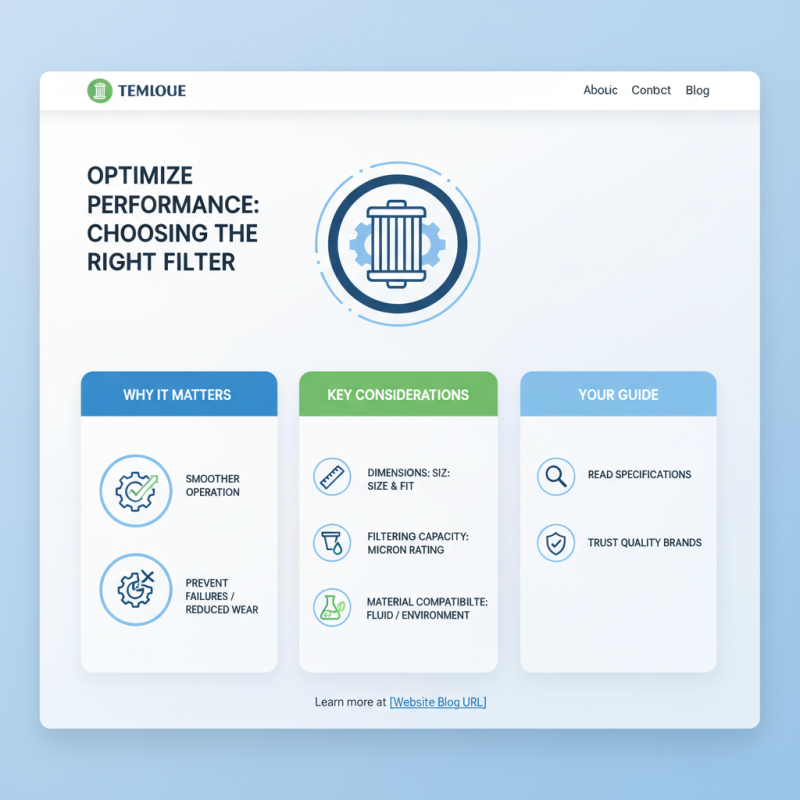

Choosing the right spare parts filter can significantly impact performance. Filters play a crucial role in keeping machinery running smoothly. A poor choice can lead to increased wear or even failures. Understanding the specifications is vital. This includes dimensions, filtering capacity, and material compatibility.

Quality matters. Inferior filters might save money upfront but can cause costly repairs later. You must prioritize durability and efficiency. However, this does not mean every expensive option is the best. Research is key. Consider your specific needs and operating conditions. Be wary of overwhelming choices, which can lead to mistakes.

Don’t forget about maintenance. Regular checks and replacements are essential for optimal function. Sometimes, filters seem fine but need replacement sooner than expected. It’s easy to overlook this detail. A well-chosen filter can extend the life of your equipment, saving you time and frustration.

Choosing the right spare parts filter starts with understanding your equipment's specific requirements. Each machine has unique characteristics. It's essential to consider factors such as size, type of contaminants, and operating environment. For instance, some filters are designed for high temperatures, while others excel in high-pressure areas. Ignoring these details can lead to inefficient performance.

Next, evaluate the filter's compatibility with your equipment. A mismatched filter can cause costly breakdowns. Check specifications and installation procedures. Not all filters fit all models. Even slight variations can affect functionality. It's wise to consult manuals and expert opinions. Some might overlook this step, leading to frustrating outcomes. Accuracy in choice is crucial for maintaining equipment longevity and reliability.

When choosing the right spare parts filter, it's crucial to understand the different types available in the market. There are primarily three categories: air filters, oil filters, and fuel filters. Each type serves a unique purpose and is designed for specific applications. For example, air filters are essential for preventing dirt and debris from entering the engine. According to industry reports, a good air filter can increase engine efficiency by up to 10%.

Understanding the specifications of these filters is vital. Not all filters are created equal; some offer higher filtration efficiency than others. Standard filtration can remove around 98% of particles, while premium filters can achieve over 99%. This difference can significantly impact the longevity and performance of machinery. Ignoring these distinctions might lead to increased wear and tear, costing more in the long run.

Another important aspect is the material used in the filters. The choice of materials impacts durability and filtration capabilities. For instance, synthetic filters often last longer and provide better filtration than traditional paper-based ones. However, they may come with a higher upfront cost. Analyzing performance data is essential. In some cases, the most expensive filter may not provide the best performance. Balancing price and quality requires careful consideration.

When selecting a spare parts filter, quality matters immensely.

Evaluating brands requires a keen eye. Look for

certifications that signal compliance with industry standards.

These endorsements often indicate reliability. It’s wise to investigate materials used in filters.

High-grade materials typically ensure better performance.

Components that degrade quickly can lead to costly repairs later on.

Reading customer reviews provides insight into brand reputation. Genuine feedback reveals real-world performance.

Be cautious of overly positive reviews; they may lack authenticity. Seek out discussions on forums for honest opinions.

Availability of customer support is also crucial. A brand that stands by its products adds considerable value.

However, not all brands provide reliable support. Keep this in mind when making a decision.

Quality assurance processes are vital in the industry. Brands that invest in testing generally offer better products.

Researching manufacturers can shed light on their practices. A transparent brand will often share its production methods.

Yet, some brands might appear trustworthy but fall short in practice.

Validate your choices with careful research to avoid regrets later on.

Remember, a smart investment today can save headaches tomorrow.

Budgeting for spare parts filters is crucial. You need to understand your organization's financial limits. An accurate budget helps avoid unexpected costs. Shop around and gather quotes. This gives a clearer picture of the market rates. Compare these prices thoughtfully to make informed choices.

Consider the quality you need. Cheaper options may save money upfront, but they could lead to failures. Failures result in higher replacement costs. Sometimes, investing more initially can prevent future expenses. It’s a balancing act between cost and reliability. Don’t overlook hidden costs, like installation or long-term maintenance.

Reflect on your choices after purchases. Did you choose wisely? Would better options be available now? These reflections can shape future budgeting decisions. Always learn from past experiences. Document what worked well and what didn’t. This can enhance your future strategies.