In the realm of heavy-duty vehicles, the significance of selecting the right truck filter cannot be overstated. According to a report by the American Trucking Associations, maintenance and operational costs account for nearly 16% of a trucking company's budget, with proper filtration playing a crucial role in maximizing engine efficiency and longevity. A high-quality truck filter not only enhances engine performance but also reduces wear and tear, ultimately minimizing downtime and repair expenses. Additionally, research shows that integrating advanced filtration systems can improve fuel efficiency by up to 5%, thus directly impacting a fleet's bottom line. This essential guide aims to provide insights into the critical aspects of choosing the best truck filters, ensuring optimal performance for both commercial and personal use.

When selecting truck filters for optimal performance, there are several key factors to consider that can significantly impact the efficiency and longevity of your vehicle. First and foremost is the filtration efficiency, which determines how effectively the filter can remove contaminants from air and fuel. Recent evaluations of vehicle cabin air filters have shown varying filtration efficiencies, with some models achieving only 56.1%. Thus, opting for filters with high filtration performance is essential to maintain clean air within the cabin and enhance overall vehicle performance.

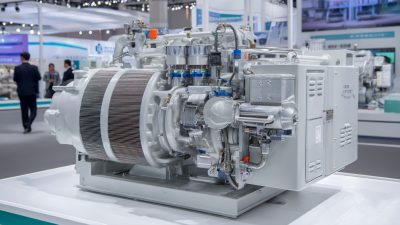

Another critical factor is the filter's compatibility with the specific make and model of the truck. Each vehicle may have unique requirements based on engine size, usage conditions, and maintenance protocols. Advanced materials, such as lightweight alloys and high-strength steels, are increasingly being integrated into truck design to improve performance. Selecting filters made from advanced materials can further complement these enhancements, offering greater durability and efficiency. Additionally, considering the filter's service life and maintenance schedule will aid in minimizing downtime, ensuring that trucks operate at peak performance throughout their lifecycle.

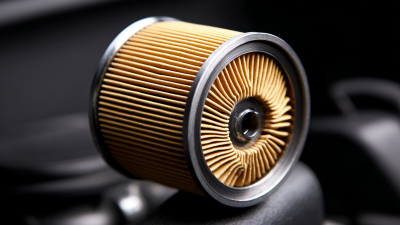

When it comes to maintaining optimal performance in trucks, understanding the different types of filters and their respective functions is crucial. Among the most common filters are oil filters, air filters, fuel filters, and cabin filters, each playing a vital role in vehicle operation. Oil filters remove contaminants from engine oil, ensuring that the engine runs smoothly and efficiently. Regular replacement of oil filters helps prevent engine wear and damage, extending the life of the vehicle.

Air filters, on the other hand, are essential for maintaining the quality of the air entering the engine. They trap dust, dirt, and other particles that can hinder performance. A clean air filter not only improves fuel efficiency but also enhances acceleration. Similarly, fuel filters play a key role in the performance of the fuel system by removing impurities from fuel before they reach the engine. Lastly, cabin filters provide clean air to the passengers by filtering out pollen, dust, and other pollutants, contributing to a more comfortable driving experience. By understanding the unique functions of each filter type, truck owners can make informed choices to maintain their vehicles' performance.

When it comes to maintaining optimal performance for your truck, choosing the right filters is crucial. Numerous brands compete in the truck filter market, but some stand out for their quality and reliability. According to a recent report by MarketsandMarkets, the global automotive filters market is projected to reach $51.9 billion by 2025, with a significant segment dedicated to truck filters. This underscores the importance of selecting filters from reputable brands that can withstand the rigors of heavy-duty operations.

Top brands such as Wix, Baldwin, and Fleetguard have made names for themselves due to their rigorous testing standards and high-quality materials. For instance, Wix filters are known for their advanced filtration technology, which has been shown to improve engine efficiency and reduce maintenance costs. Meanwhile, Baldwin filters offer robust construction and superior dirt-holding capacity, making them ideal for truck drivers who operate in challenging environments. A study by the Automotive Aftermarket Suppliers Association (AASA) indicates that using high-quality filters can extend engine life by up to 30%, emphasizing the need for careful brand selection for anyone serious about truck maintenance.

| Filter Type | Material | Efficiency Rating | Price Range | Warranty Period |

|---|---|---|---|---|

| Oil Filter | Synthetic Fiber | 99% | $10 - $30 | 1 Year |

| Air Filter | Paper | 95% | $15 - $40 | 2 Years |

| Fuel Filter | Metal | 98% | $20 - $50 | 1 Year |

| Cabin Air Filter | Activated Carbon | 90% | $10 - $35 | 1 Year |

Proper maintenance and timely replacement of truck filters are crucial for ensuring the optimal performance and longevity of your vehicle. Regularly inspecting the air, oil, and fuel filters can prevent unnecessary wear and tear on the engine and enhance fuel efficiency. Typically, air filters should be checked every 15,000 to 30,000 miles, while oil filters should be replaced during oil changes, which may occur every 5,000 to 7,500 miles, depending on usage and oil type. Fuel filters often need to be replaced every 30,000 to 50,000 miles, but it's wise to refer to the truck's manual for specific recommendations.

In addition to routine checks, proper cleaning practices can extend the life of filters. For air filters, using compressed air to remove debris and dirt can maintain airflow and prevent clogging, while oil filters require a complete replacement when the oil is changed. For fuel filters, ensuring the fuel system is free from contaminants before installation will help avoid premature failure. By adopting these maintenance practices, truck owners can optimize their vehicle's performance, ensuring it runs smoothly and efficiently over the long term.

When selecting truck filters, avoiding common mistakes can significantly enhance performance and efficiency. One frequent error is opting for low-cost filters without considering quality. While budget-friendly options may seem appealing, they often lack the necessary filtration capabilities and durability. Investing in high-quality filters can prevent engine wear and improve overall vehicle performance.

Tip: Always check filter specifications against your truck’s requirements. This ensures compatibility and optimal functionality.

Another mistake is overlooking the maintenance schedule for filter replacement. Many truck owners underestimate the importance of regular changes, leading to clogged filters that can adversely affect fuel efficiency and engine performance. Following the manufacturer’s recommendations for filter changes is crucial for maintaining your truck's peak performance.

Tip: Create a maintenance log to track filter changes and other essential services, helping to avoid unnecessary downtimes.

Lastly, failing to consider the type of driving conditions can lead to poor filter choices. Trucks that frequently operate in dusty or harsh environments require more robust filters to handle the increased dirt and debris. Assessing the specific driving conditions is vital in selecting the right filters tailored to those needs.