In today's fast-paced industrial landscape, ensuring the seamless operation of machinery is paramount. A critical aspect of effective maintenance strategies is the utilization of a **Spare Parts Filter**. This tool plays a vital role in streamlining the identification and procurement of essential spare parts, ultimately enhancing maintenance efficiency. When maintenance teams can quickly locate and acquire the necessary components, they can reduce downtime and prevent costly disruptions in production processes.

The importance of a **Spare Parts Filter** cannot be overstated, as it aids organizations in managing their inventory wisely. By categorizing and prioritizing spare parts based on factors such as usage frequency and criticality, teams can make informed decisions that align with operational needs. This strategic approach not only saves valuable time but also optimizes costs associated with overstocking or emergency procurements.

In this article, we will delve into the intricacies of employing a **Spare Parts Filter**, exploring practical steps and best practices that maintenance teams can adopt. Understanding how to effectively implement this filtering system is essential for any organization aiming to enhance their maintenance processes and achieve operational excellence.

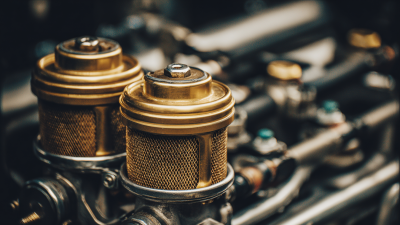

The role of spare parts filters in maintenance efficiency cannot be underestimated. Spare parts filters serve as a crucial element in the maintenance toolkit, ensuring that only the highest quality components are used for repairs and replacements. This is particularly important in sectors where machinery and equipment operate under extreme conditions, as low-quality parts can lead to breakdowns and prolonged downtimes. By streamlining the procurement process and reducing the risk of equipment failure, spare parts filters provide maintenance teams with the confidence to execute their tasks effectively.

Moreover, the strategic use of spare parts filters allows organizations to optimize their inventory management. By identifying the most critical spare parts necessary for maintenance, companies can prevent overstocking while ensuring that essential components are readily available when needed. This balance not only cuts costs but also enhances the overall responsiveness of maintenance operations. Consequently, spare parts filters emerge as a vital aspect of a company’s maintenance strategy, reinforcing the foundation for a more efficient and effective operation.

Efficient spare parts management plays a crucial role in minimizing downtime across various industries. When machinery or equipment fails, the availability of the right spare parts can determine how quickly operations can resume. Delays in obtaining essential components can lead to extended periods of inactivity, resulting in lost productivity and increased operational costs. By efficiently managing spare parts inventories, businesses can significantly reduce the time taken to repair and maintain critical assets, ensuring a seamless workflow.

Furthermore, quantifying downtime associated with inefficient spare parts management can highlight the financial implications of neglecting this aspect of maintenance. Companies that do not prioritize spare parts availability often face hidden costs, such as overtime labor expenses and impact on production schedules. By analyzing historical downtime data and correlating it with spare parts lead times, businesses can identify patterns and make informed decisions to optimize inventory levels. In doing so, they not only enhance their maintenance strategies but also contribute to overall efficiency and profitability.

The demand for quality spare parts filters is witnessing a significant uptick across various industries, driven by an increasing focus on maintenance efficiency and operational reliability. According to a report from MarketsandMarkets, the global automotive filter market is projected to reach USD 41.8 billion by 2026, growing at a CAGR of 6.6% during the forecast period. This growth reflects a heightened awareness of the critical role that high-quality filters play in enhancing equipment lifespan and overall performance.

Moreover, industries such as manufacturing, aerospace, and energy are emphasizing the need for superior spare parts filters to mitigate downtime and reduce maintenance costs. A recent study by Mordor Intelligence highlights that the industrial filtration market is expected to grow to USD 26.6 billion by 2025, driven by stringent regulations and the rising demand for cleaner operations. As organizations strive to achieve operational excellence, investing in top-notch spare parts filters is becoming integral in ensuring machinery operates smoothly and efficiently, ultimately leading to increased productivity and lower operational risks.

Efficient maintenance heavily relies on the strategic management of spare parts, which significantly contributes to cost savings for manufacturers. In various industries, the optimization of spare parts inventory can lead to substantial financial benefits. For instance, in the aviation sector, the complexity of managing spare parts necessitates a delicate balance between having sufficient stock and avoiding excess inventory. Effective strategies can help airlines streamline their operations and mitigate costs without compromising service quality.

Additionally, insights from maintenance strategy optimization highlight how companies can realize millions in savings. A recent case study showed that a LNG producer achieved $135 million in cost reductions by refining its maintenance protocols, which included smarter spare parts management. This approach not only reduces waste but also enhances overall operational efficiency, proving that investing in spare parts optimization is not just a cost-saving measure but a critical element for sustained competitive advantage. As industries evolve with technological advancements and strategic investments, prioritizing spare parts management becomes essential for long-term success and profitability.

In various industries, the implementation of spare parts filters has demonstrated significant advantages through real-world case studies. For instance, a leading aerospace manufacturer revamped its maintenance strategy by integrating a spare parts filter system. This approach allowed them to categorize parts based on usage frequency and criticality. As a result, they reduced downtime by 25% and cut unnecessary inventory costs, ensuring that essential components were readily available while minimizing excess stock.

Another compelling case is found in the automotive sector, where a renowned car manufacturer adopted a sophisticated filtering system for spare parts. By analyzing historical data on part failures and maintenance records, the company was able to predict which components were most likely to require replacement. This proactive stance led to a 30% increase in operational efficiency and enhanced customer satisfaction, as vehicles remained in service longer and required fewer repairs. These success stories exemplify how effective spare parts filtering not only streamlines maintenance processes but also significantly boosts overall productivity and reliability.