In today's competitive market, optimizing machinery performance is crucial. As an expert in the Spare Parts Filter industry, Dr. Emily Carter emphasizes, "Choosing the right filters can drastically enhance efficiency." This statement highlights the need for effective replacement parts to maintain productivity.

With various Spare Parts Filter options, businesses often feel overwhelmed. Selecting the ideal filter impacts not only performance but also long-term costs. Each type of filter comes with its own advantages and challenges. Many companies overlook the importance of regular filter upgrades. They may settle for outdated options, which can lead to inefficiencies, breakdowns, or increased operational costs.

Incorporating top-quality Spare Parts Filters is essential. Yet, an understanding of each option can be daunting. It requires thorough research and sometimes, trial and error. The industry is evolving, and businesses must adapt to maintain a competitive edge. Failure to do so could mean losing valuable resources and revenue.

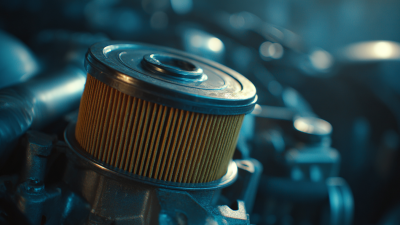

When it comes to enhancing performance, spare parts filters play a vital role. Poorly functioning filters can lead to decreased efficiency and increased costs. Industry studies indicate that up to 30% of machinery downtime results from filter failures. This statistic highlights the need for robust filter solutions.

The right filter choice impacts fuel consumption and engine performance. For instance, a high-quality air filter can improve fuel efficiency by 10-15%. Interestingly, many operators overlook filter maintenance. Neglecting regular checks can lead to expensive repairs and reduced lifespan. Data also show that over 20% of equipment failures are directly linked to inadequate filtration.

Understanding the type of contaminants is crucial. Dust, debris, and moisture can severely limit performance. A study by a leading industry group revealed that replacing filters regularly can extend machinery life by 20%. However, many businesses fail to implement a proactive filter replacement schedule. This oversight can result in significant operational setbacks. Rethinking maintenance strategies may be essential for better performance.

In the world of machinery, spare parts filters play a crucial role in maintaining optimal performance. Various types of filters are available, each designed to meet specific needs.

Air filters, oil filters, and fuel filters are the most common. Air filters prevent contaminants from entering the engine, thereby improving efficiency. According to a report by industry experts, maintaining clean air filters can enhance engine performance by up to 10%.

Oil filters are equally important. They remove particulates and contaminants from engine oil. A study by the Global Filter Association highlights that using quality oil filters can extend engine life by an impressive 20%. Fuel filters clean the fuel before it reaches the engine, ensuring smooth operation and optimal combustion. However, many users overlook their maintenance. Ignoring the state of these filters can lead to subpar performance and costly repairs.

It's essential to understand that not all filters are created equal. While the initial cost of high-quality filters may deter some, the long-term benefits are undeniable. A survey revealed that nearly 30% of equipment failures are linked to inadequate filtration. These figures should compel users to assess their filter choices. Regular inspection and timely replacement can significantly improve performance and reliability.

When selecting spare parts filters, performance is paramount. It’s crucial to understand key features that directly affect efficiency. Efficiency ratings, for instance, often define how well a filter can capture contaminants. Reports indicate that filters with a higher efficiency rating can reduce engine wear and extend lifespan by around 30%. This statistic highlights the importance of making informed choices when selecting filters for any application.

Material composition is another critical factor. The choice between synthetic and cellulose media greatly influences filtration performance and durability. Synthetic filters typically offer better dirt-holding capacity and can last longer under harsh conditions. According to industry data, synthetic options can outperform cellulose by up to 50% in contaminant capture. However, consider the cost-benefit analysis carefully. While synthetic may offer superior performance, they also tend to be pricier.

End-users should also evaluate the installation and maintenance aspects. Filters that are easy to install save time and labor costs. Some complex filters may require specialized tools or skills, making them less accessible. Reports show that inadequate installation can lead to up to 20% drop in efficiency. Regular maintenance schedules should also be reviewed, as neglecting this can lead to premature wear of engine components. Understanding these elements can dramatically impact overall performance and maintenance costs.

When it comes to enhancing vehicle performance, spare parts filters play a key role. Many brands offer diverse options tailored for various needs. Choosing the right filter can significantly improve engine efficiency and longevity. The right choice might not always be straightforward. Different manufacturers have unique technologies each claiming superior benefits. Yet, the real-world performance may vary depending on your specific vehicle type.

Some brands focus on high-flow filters, designed to maximize airflow and enhance power output. These filters often attract those seeking more horsepower. Others prioritize filtration efficiency, capturing finer particles to protect the engine. It’s crucial to determine what aspect enhances your vehicle's performance. Moreover, user feedback often reveals gaps in these products. Some filters may perform well initially but become ineffective over time.

When considering options, research and user experiences can guide your decision. Read reviews and check compatibility with your model. The wrong filter can lead to reduced performance instead of enhancement. Reflect on what your vehicle truly needs before making a purchase. The right choice is not just about brand reputation but also about your individual requirements and conditions.

| Filter Type | Material | Efficiency Rating (%) | Max Flow Rate (L/min) | Typical Use |

|---|---|---|---|---|

| Oil Filter | Synthetic Fiber | 99.7 | 30 | Automobile Engines |

| Air Filter | Paper | 95 | 70 | HVAC Systems |

| Fuel Filter | Polypropylene | 98 | 45 | Commercial Vehicles |

| Fuel Water Separator | Glass Fiber | 99.9 | 20 | Marine Applications |

| Cabin Air Filter | Activated Carbon | 99 | 50 | Passenger Vehicles |

| Transmission Filter | Steel Mesh | 98 | 25 | Automated Transmissions |

| Hydraulic Filter | Cellulose | 99.5 | 60 | Construction Equipment |

| Biodiesel Filter | Polyester | 98.5 | 40 | Alternative Fuels |

| Mesh Strainer | Stainless Steel | 95 | 80 | Inline Filtration |

| Pre-Filter | Polypropylene | 90 | 55 | Industrial Applications |

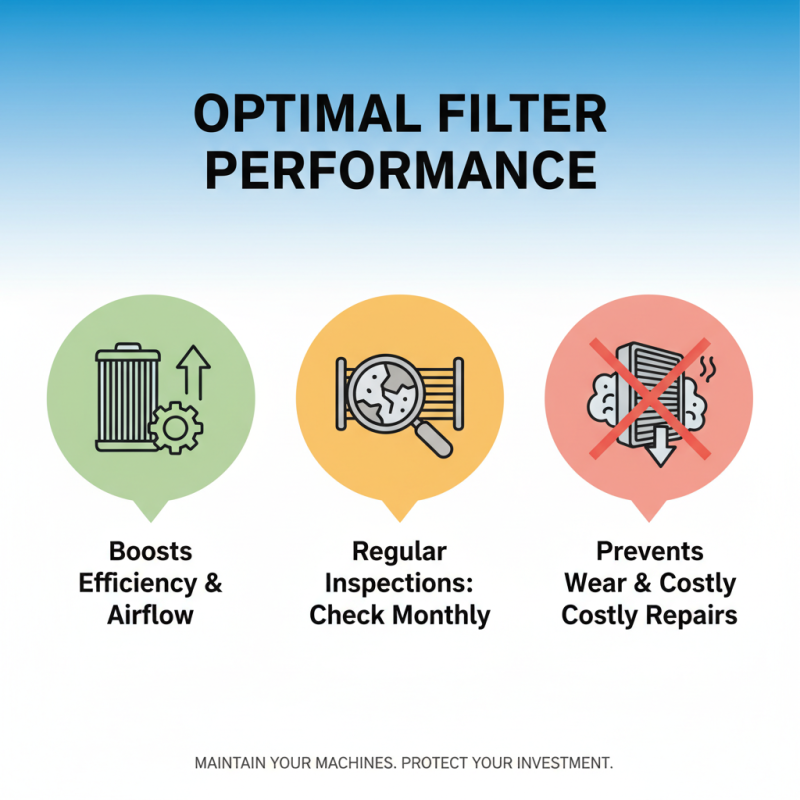

Maintaining optimal filter performance is crucial for any machinery or vehicle. Regular inspections are necessary to catch early signs of wear, such as cracks or dirt accumulation. A dirty filter can restrict airflow and decrease efficiency. Checking filters every month helps catch these issues before they escalate.

It’s important to know when to replace filters. Even high-quality filters have a lifespan. Consider how often your equipment runs. If you're using it frequently, replace filters every few months. Neglecting this can lead to significant performance drops. Additionally, clean or replace any associated parts when changing filters.

Look for signs of performance changes. If your engine feels sluggish, or there's unusual noise, check your filters. Sometimes, uneven performance can result from minor blockages. Awareness of these details can enhance machinery longevity. Regular maintenance fosters a cycle of efficiency, which is critical for any operation.